Pyrolytic topping of coal-algae composite under mild inert conditions

DOI:

https://doi.org/10.17159/2413-3051/2019/v30i3a5763Keywords:

fossil bio-crude oil, resultant char, mild pyrolysis, coal-algae compositeAbstract

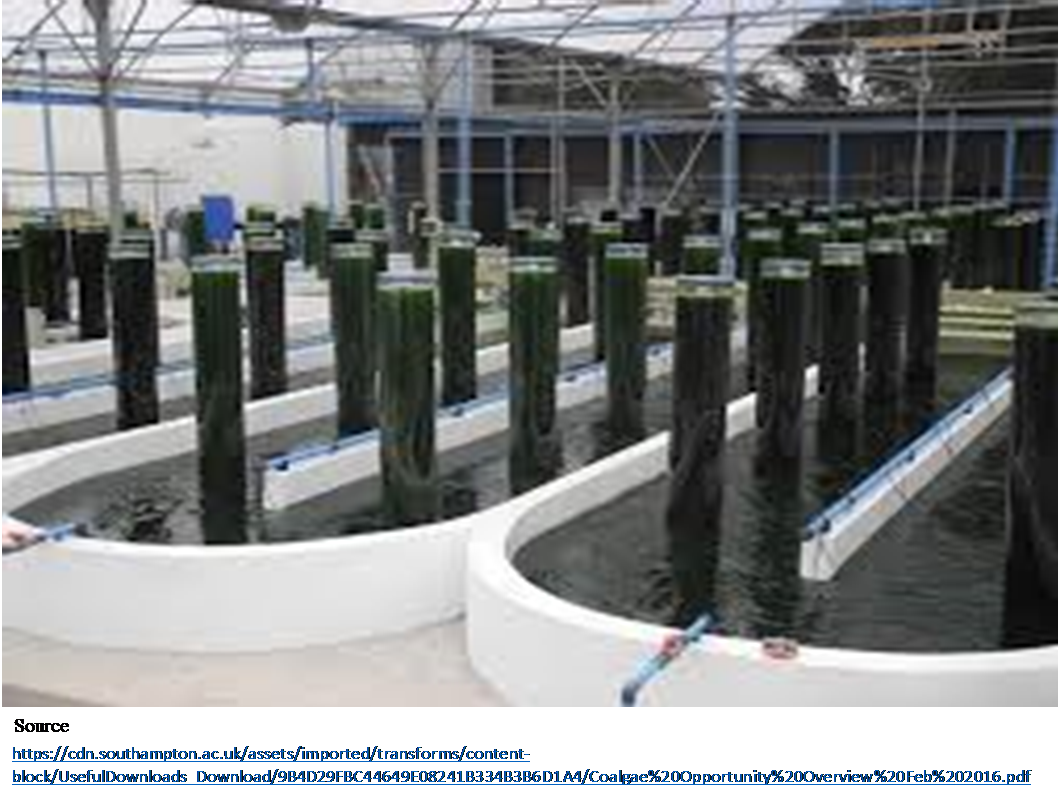

Co-processing of coal and biomass has been a focus of several research studies aimed at addressing the negative environmental attributes associated with thermal processing of coal alone, as well as improving the thermal behaviour of coal. Biomass materials are regarded as a clean, renewable source, so thermal co-processing of biomass with coal is considered an effective way to utilise coal in a sustainable manner. In this study, coal fines were blended with Scenedesmus microalgae slurry to form a coal-algae composite. Pyrolytic topping of coal-algae composite was performed at 450 ºC on a batch reactor. Parent fuels and resultant chars were analysed for their proximate properties using an Eltra thermostep TGA; a Vario EL cube Elementar was used to determine the elemental composition of the chars and oils. A simulated distillation (SimDis) method was used to determine the boiling point distribution of the produced oils. The objective of the study was to examine the effects of microalgae slurry on the pyrolytic behaviour of waste coal fines with respect to product yields, composition and quality. Results showed that the yields of volatile components from pyrolysis of coal-algae composite were high compared with those from pyrolysis of coal alone. A significant degree of deoxygenation, dehydrogenation and denitrification was observed in coal-algae char than coal char. SimDis results showed that the fossil bio-crude oil has different boiling point characteristics from coal tar. The study has shown that microalgae slurry has potential to influence the pyrolytic behaviour of waste coal under mild inert conditions.

Downloads

References

Baloyi, H and Dugmore, G. 2018. Influences of microalgae biomass on the thermal behaviour of waste coal fines. Journal of Energy in Southern Africa 30(1): 1-7. http://dx.doi.org/10.17159/2413-3051/2018/v30i1a5763.

Channiwala, S.A and Parikh, P.P. 2002. A unified correlation for the estimation HHV of solid, liquid and gaseous fuels. Fuel 81(8): 1051-1063. https://doi.org/10.1016/S0016-2361(01)00131-4.

Chen, C., Ma, Α and He, Y. 2012. Co-pyrolysis characteristics of microalgae Chlorella vulgaris and coal through TGA. Bioresource Technology 117: 264-273. https://doi.org/10.1016/j.biortech.2012.04.077.

Demirbas, A. 2003. Sustainable cofiring of biomass with coal. Energy Conversion & Management 44(9): 1465-1479. https://doi.org/10.1016/S0196-8904(02)00144-9.

Escallon, M.M. 2008. Petroleum and petroleum/coal blends as feedstocks in laboratory scale and pilot scale cokers to obtain carbons of potentially high value. PhD thesis, Pennsylvania State University, USA.

Ferrara, F., Orsini, A., Plaisant, A and Pettinau, A. 2014. Pyrolysis of coal, biomass and their blends: Performance assessment by thermogravimetric analysis. Bioresource Technology 171: 433-441. https://doi.org/10.1016/j.biortech.2014.08.104.

Idris, S.S., Rahman, N.A., Ismail, K., Alias, A.B., Rashid, Z.A and Aris, M.J. 2010. Investigation on thermochemical behaviour of low rank Malaysian coal, tar palm biomass and their blends during pyrolysis via thermo gravimetric analysis. Bioresource Technology 101(12): 4584-4592. https://doi.org/10.1016/j.biortech.2010.01.059.

Kirtania, K and Bhattacharya, S. 2013. Pyrolysis kinetics and reactivity of algae-coal blends. Biomass and Bioenergy 55: 291-298. https://doi.org/10.1016/j.biombioe.2013.02.019.

Kumabe, K., Hanaoka, T., Fujimoto, S., Minowa, T and Sakanishi, K. 2007. Co-gasification of woody biomass and coal with air and steam. Fuel 86(5-6): 684-689. https://doi.org/10.1016/j.fuel.2006.08.026.

Li, S., Chen, X., Wang, L., Liu, A and Yu, G. 2013. Co-pyrolysis behaviors of saw dust and Shenfu coal in drop tube furnace and fixed bed reactor. Bioresource Technology 148: 24-29. http://dx.doi.org/10.1016/j.biortech.2013.08.126.

Park, D.K., Kim, S.D., Lee, S.H and Lee, J.G. 2010. Co-pyrolysis characteristics of sawdust and coal blend in TGA and a fixed bed reactor. Bioresource Technology 101(15): 6151-6156. https://doi.org/10.1016/j.biortech.2010.02.087.

Patel, B and Hellgardt, K. 2015. Hydrothermal upgrading of algae paste in a continuous flow reactor. Bioresource Technology 191: 460-468.

http://dx.doi.org/10.1016/j.biortech.2015.04.012.

Pedersen, L.S., Nielsen, H.P., Kiil S., Hansen, L.A., Dam-Johansen, K., Kildsig F., Christensen, J., Jespersen, P. 1996. Full-scale co-firing of straw and coal. Fuel 75 (13): 1584-1590.

Quan, C and Gao, N. 2016. Copyrolysis of biomass and coal: A review of effects of parameters, product properties, and synergistic mechanisms. BioMed Research International. Article ID 6197867, 1–11.

Seo, G.K, Park, S.S, Kim, T.Y., Hwang, J and Yu, T. 2011. Study of coal pyrolysis by thermo-gravimetric analysis (TGA) and concentration measurements of the evolved species. Journal of Analytical and Applied Pyrolysis 92(1): 209-216. https://doi.org/10.1016/j.jaap.2011.05.012.

Serio, M.A, Hamblen, D.G., Markham, J.R and Solomon, P.R. 1987. Kinetics of volatile product evolution in coal pyrolysis: Experiment and theory. Energy & Fuels 1(2): 138-152. https://doi.org/10.1021/ef00002a002.

Soncini, R. M., Means, N.C and Weiland, N.T. 2013. Co-pyrolysis of low rank coals and biomass: Product distribu-tions. Fuel 112: 74–82. https://doi.org/10.1016/j.fuel.2013.04.073.

Taba, L.E., Irfan, M.F., Daud, W.A.M.W and Chakrabarti, M. H. 2012. The effect of temperature on various parameters in coal, biomass and co-gasification: A review. Renewable and Sustainable Energy16(8): 5584-5596. http://dx.doi.org/10.1016/j.rser.2012.06.015.

Veras, C. A. G., Carvalho, J.A and Ferreira, M.A. 2002. The chemical percolation devolatilization model applied to the devolatilization of coal in high intensity acoustic fields. Journal of the Brazilian Chemical Society 13(3): 358-367. http://dx.doi.org/10.1590/S0103-50532002000300001.

Vreugdenhil, B.J and Zwart, R.W.R. 2009. Tar formation in pyrolysis and gasification. Energy Research Centre of the Netherlands. ECN-E--08-087, Petten.

Vuthaluru, H.B. 2004. Thermal behaviour of coal/biomass blends during co-pyrolysis. Fuel Processing Technology 85(2-3): 141–155. https://doi.org/10.1016/S0378-3820(03)00112.

Wei, L., Zhang, L and Xu, S. 2011. Effects of feedstock on co-pyrolysis of biomass and coal in a free-fall reactor. Jour-nal of Fuel Chemistry and Technology 39(10): 728-734. https://doi.org/10.1016/S1872-5813(11)60044-3.

Wu, Z., Wang, S., Zhao, J., Chen, L., Meng, H. 2014. Synergistic effect on thermal behavior during co-pyrolysis of lignocellulosic biomass model components blend with bituminous coal. Bioresource Technology 169: 220-228. https://doi.org/10.1016/j.biortech.2014.06.105.

Yu, J., Lucas, J.A and Wall, T.F. 2007. Formation of the structure of chars during devolatilization of pulverized coal and its thermo properties: A review. Progress in Energy and Combustion Science 33(2): 135-170. http://dx.doi.org/10.1016/j.pecs.2006.07.003.

Downloads

Published

Issue

Section

License

Copyright (c) 2019 Hope Baloyi, Gary Dugmore

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

.png)