The feasibility of using biogas generated from livestock manure as an alternative energy source: A South African perspective

DOI:

https://doi.org/10.17159/2413-3051/2023/v34i1a17021Abstract

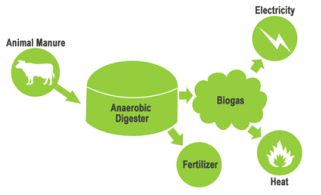

Electricity usage has risen tremendously over the years, as has its price. This resulted in an increase in the quest for less expensive, viable, and ecologically acceptable means of producing energy for electricity. Currently, the primary source of power in South Africa is sourced from fossil fuels, which have negative environmental consequences. The use of biogas as an alternative can mitigate the impacts of using fossil fuels to generate power. This study has examined the availability and accessibility of waste that may be utilized to generate biogas using common South African livestock excrement. A typical South African home uses 31 kWh of power daily, which equates to 111.6 MJ of energy. According to calculations, about 30 m3 of biogas is needed to produce enough energy to power a household. For the generation of mono-digestion biogas, 12 beef cows, 8 dairy cows, 3898 chickens, 156 pigs, 281 sheep and 300 goats would be needed to meet this need. Moreover, the livestock dung required to meet the daily requirement of 31 kWh is 713 kg for beef and dairy cows, 390 kg for chickens, 468 kg for pigs, 506 kg for sheep and 466 kg for goats. Co-digestion of various wastes is nonetheless a viable and advised method for enhancing the amount and quality of biogas.

Downloads

References

Aaron O’Neill. 2023. South Africa: Unemployment rate from 2003 to 2022, Statista. https://www.statista.com/statistics/370516/unemployment-rate-in-south-africa/ (Accessed: 16 December 2023).

Abanades, S., Abbaspour, H., and Ahmadi, A. 2022. A critical review of biogas production and usage with legislations framework across the globe. International Journal of Environmental Science and Technology. Springer Science and Business Media Deutschland GmbH, pp. 3377–3400. https://doi.org/10.1007/s13762-021-03301-6.

Abebe, M.A. 2017. Characterisation of fruit and vegetable waste with cow dung for maximizing the biogas yield. Inter-national Journal of Scientific Engineering and Science, 1(1), pp. 26–32. https://www.academia.edu/33195394/Characterisation_of_Fruit_and_Vegetable_Waste_with_Cow_Dung_for_Maximizing_the_Biogas_Yield (Accessed: 1 February 2024).

Achinas, S., Li, Y., Achinas, V. and Euverink, G. 2018. Influence of sheep manure addition on biogas potential and methanogenic communities during cow dung digestion under mesophilic conditions. Sustainable Environment Research, 28(5), pp. 240–246. https://doi.org/10.1016/j.serj.2018.03.003.

Ahlberg-Eliasson, K., Westerholm, M., Isaksson, S. and Schnürer, A. 2021. Anaerobic digestion of animal manure and influence of organic loading rate and temperature on process performance, microbiology, and methane emission from digestates. Frontiers in Energy Research, 9. https://doi.org/10.3389/fenrg.2021.740314.

Alfa, M.I., Adie, D.B., Igboro, S.B., Oranusi, U.S., Dahunsi, S.O. and Akali., D.M. 2014. Assessment of biofertilizer quality and health implications of anaerobic digestion effluent of cow dung and chicken droppings. Renewable Energy, 63, pp. 681–686. https://doi.org/10.1016/j.renene.2013.09.049.

Alham, N.R., Siregar, I.R., Prabowo, B.D., Margono, W.C., Azhari, U.L. and Larasati, T.D. 2022. Utilization of goat manure towards PLTB (biogas) prototypes in simple way. In International conference on tropical studies and its applications, pp. 1–8. https://e-journals2.unmul.ac.id/index.php/ictrops6th/article/download/91/73/521 (Accessed: 22 November 2023).

Alma’atah, B.M., Alzoubi, A.I. and Alkhamis, T.M. 2021. Biogas production from sheep manure by a simulated un-derground burial system heated with cascade-controlled solar water heated system, as an indicator of biomass po-tential contribution to power mix in Jordan. Journal of Environmental Protection, 12(02), pp. 125–140. https://doi.org/10.4236/jep.2021.122009.

American Society of Agricultural Engineers, A. 2003. ASAE D384.1 FEB03 Manure production and characteristics. http://large.stanford.edu/publications/coal/references/docs/ASAEStandard.pdf (Accessed: 1 February 2024).

Aranguren, D.D., Acosta, M.T., Rodríguez, M.O., Seirra, R., Gordillo, R., and Gordillo, G. 2021. Analysis of the poten-tial biogas production from pig manure in pig farms located in Colombia. In 29th European Biomass Conference and Exhibition, pp. 600–604. https://doi.org/10.5071/29thEUBCE2021-2CV.3.13.

Arromdee, P., Nawalerskasama, A. and Saewong, N. 2017. Economic analysis of electricity generation from chicken manure by plug flow anaerobic digester and CSTR anaerobic digester. Silpakorn University Journal of Social Sci-ences, 17(3), pp. 27–50. https://thaiscience.info/Journals/Article/SUIJ/10988630.pdf (Accessed: 16 December 2023).

Arshad, M., Ansari, A.R., Qadir, R., Tahir, M.H., Nadeem, A., Mehmood, T., Alhumade, H. and Khan, N. 2022. Green electricity generation from biogas of cattle manure: an assessment of potential and feasibility in Pakistan. Frontiers in Energy Research, 10, p.911485. https://doi.org/10.3389/fenrg.2022.911485.

Beily, M.E., Young, B.J., Bres, P.A., Riera, N.I., Wang, W., Crespo, D.E. and Komilis, D. 2023. Relationships among physicochemical, microbiological, and parasitological parameters, ecotoxicity, and biochemical methane potential of pig slurry. Sustainability, 15(4), p.3172. https://doi.org/10.3390/su15043172.

Bertholt, S.S.H., Kewir, T.J., Merlain, D.K.B., Tchoumboue, N.K., Alexi, L.K., Jospin, T.G. and Leonel, N.W.B. 2021. Characterization of wet mesophilic biomethanization of three types of materials: chicken dung, rabbit poop and pig slurry. International Journal of Sustainable and Green Energy, 10 (4), p.145-154. 10.11648/j.ijrse.20211004.14

Bożym, M. and Siemiątkowski, G. 2020. Assessment of composition changes, stability degree and the potential of biogas formation of sewage sludge composts during maturation process. Waste and Biomass Valorization, 11(8), pp. 4081–4091. https://doi.org/10.1007/s12649-019-00736-4.

Buivydas, E., Navickas, K., Venslauskas, K., Žalys, B., Župerka, V. and Rubežius, M. 2022. Biogas production en-hancement through chicken manure co-digestion with pig fat. Applied Sciences, 12(9), p.4652. https://doi.org/10.3390/app12094652.

Busato, C.J., Da Ros, C., Pellay, R., Barbierato, P. and Pavan, P. 2020. Anaerobic membrane reactor: biomethane from chicken manure and high-quality effluent. Renewable Energy, 145, pp.1647-1657. https://doi.org/10.1016/j.renene.2019.07.088.

Calbry-Muzyka, A., Madi, H., Rüsch-Pfund, F., Gandiglio, M. and Biollaz, S. 2022. Biogas composition from agricul-tural sources and organic fraction of municipal solid waste. Renewable Energy, 181, pp.1000-1007. https://doi.org/10.1016/j.renene.2021.09.100.

Cestonaro, T., de Mendonça Costa, M.S.S., de Mendonça Costa, L.A., Rozatti, M.A.T., Pereira, D.C., Lorin, H.E.F. and Carneiro, L.J. 2015. The anaerobic co-digestion of sheep bedding and⩾ 50% cattle manure increases biogas production and improves biofertilizer quality. Waste Management, 46, pp.612-618. https://doi.org/10.1016/j.wasman.2015.08.040.

Chinwendu, S., Chibueze, U. and Tochukwu, E. 2013. Anaerobic digester considerations of animal waste. American Journal of Biochemistry, 2013(4), pp. 93–96. https://doi.org/10.5923/j.ajb.20130304.02.

ClarkeEnergy. 2024. CHP efficiency for biogas, Biogas. https://www.clarke-energy.com/2013/chp-cogen-efficiency-biogas/ (Accessed: 29 January 2024).

Dimitrov, R., Ivanov, Z., Zlateva, P. and Mihaylov, V. 2019. Optimization of biogas composition in experimental stud-ies. In E3S Web of Conferences (Vol. 112, p. 02007). EDP Sciences. https://doi.org/10.1051/e3sconf/201911202007.

Elasri, O. and El amin Afilal, M. 2016. Potential for biogas production from the anaerobic digestion of chicken drop-pings in Morocco. International Journal of Recycling of Organic Waste in Agriculture, 5(3), pp. 195–204. https://doi.org/10.1007/s40093-016-0128-4.

Elhenawy, Y., El-Kadi, S., Elsawy, K., Abdelmotalip, A. and AbdelrahmanIbrahim, I. 2021. Biogas production by an-aerobic digestion of cow dung using floating type fermenter. Journal of Environmental Treatment Techniques, 9(2), pp.446-451. https://doi.org/10.47277/JETT/9(2)451.

Energypedia. 2016. Electricity Generation from Biogas. Energypedia. https://energypedia.info/wiki/Electricity_Generation_from_Biogas#:~:text=In%20most%20cases%2C%20biogas%20is,design%20of%20an%20electric%20motor. (Accessed: 26 June 2023).

Ezekoye, V.A. and Ezekoye, B.A. 2009. Characterization and storage of biogas produced from the anaerobic digestion of cow dung, spent grains/cow dung, and cassava peels/rice husk. The Pacific Journal of Science and Technology, 10(2), pp. 898–904. http://www.akamaiuniversity.us/PJST.htm.

Garg, S., Attia, B., Handler, B. and Bazilian, M. 2022. Demand in the dark: Estimating the true scale of unmet electrici-ty demand in Sub-Saharan Africa. The Electricity Journal, 35(8), p.107189. https://doi.org/10.1016/j.tej.2022.107189.

Gaworski, M., Jabłoński, S., Pawlaczyk-Graja, I., Ziewiecki, R., Rutkowski, P., Wieczyńska, A., Gancarz, R. and Łukaszewicz, M. 2017. Enhancing biogas plant production using pig manure and corn silage by adding wheat straw processed with liquid hot water and steam explosion. Biotechnology for biofuels, 10, pp.1-13. https://doi.org/10.1186/s13068-017-0922-x

Greater Good SA. 2022. Average Electricity Consumption Per Household in South Africa, Greater Good. https://www.myggsa.co.za/how-much-kwh-does-a-house-use-in-south-africa/ (Accessed: 2 June 2023).

Grimsby, L.K., Gulbrandsen, L., Eik, L.O., Msalya, G. and Kifaro, G.C. 2016. The prospect of biogas among small-holder dairy goat farmers in the Uluguru Mountains, Tanzania. African Journal of Food, Agriculture, Nutrition and Development, 16(1), pp.10723-10737. https://doi.org/10.18697/ajfand.73.15650.

Hamzah, A.F., Hamzah, M.H., Man, H.C., Jamali, N.S., Siajam, S.I. and Ismail, M.H. 2023. Effect of organic loading on anaerobic digestion of cow dung: Methane production and kinetic study. Heliyon, 9(6), p. e16791. https://doi.org/10.1016/j.heliyon.2023.e16791.

Haryanto, A., Marotin, F., Triyono, S. and Hasanudin, U. 2017. Developing a family-size biogas-fueled electricity gen-erating system. Int. Journal of Renewable Energy Development, 6(2), pp.111-118. https://doi.org/10.14710/ijred.6.2.111-118.

Ji, J.L., Chen, F., Liu, S., Yang, Y., Hou, C. and Wang, Y.Z. 2022. Co-production of biogas and humic acid using rice straw and pig manure as substrates through solid-state anaerobic fermentation and subsequent aerobic compost-ing. Journal of Environmental Management, 320, p.115860. https://doi.org/10.1016/j.jenvman.2022.115860.

Kabeyi, M.J.B. and Olanrewaju, O.A. 2022. Biogas production and applications in the sustainable energy transition. Journal of Energy, 2022, pp. 1–43. https://doi.org/10.1155/2022/8750221.

Kaur, H. and Kommalapati, R.R. 2021. Optimizing anaerobic co-digestion of goat manure and cotton gin trash using biochemical methane potential (BMP) test and mathematical modelling. SN Applied Sciences, 3(8). https://doi.org/10.1007/s42452-021-04706-1.

Kuo, J. and Dow, J. 2017. Biogas production from anaerobic digestion of food waste and relevant air quality implica-tions. Journal of the Air and Waste Management Association, 67(9), pp. 1000–1011. https://doi.org/10.1080/10962247.2017.1316326.

Kusmiyati, K., Wijaya, D.K., Hartono, B.R., Shidik, G.F. and Fudholi, A. 2023. Harnessing the power of cow dung: Exploring the environmental, energy, and economic potential of biogas production in Indonesia. Results in Engi-neering, 20, p.101431. https://doi.org/10.1016/j.rineng.2023.101431.

Lami, M., Chimdessa Egigu, M. and Chimdessa, M. 2017. Biogas Production from co-digestion of poultry manure and orange peel through thermal pre-treatments in batch fermentation. Technology, and Sciences (ASRJETS) Ameri-can Scientific Research Journal for Engineering, 38(2), pp. 226–246. http://asrjetsjournal.org/.

Lerede, D. and Savoldi, L. 2023. Might future electricity generation suffice to meet the global demand?. Energy Strate-gy Reviews, 47, p. 101080. https://doi.org/10.1016/j.esr.2023.101080.

Lisowyj, M. and Wright, M.M. 2020. A review of biogas and an assessment of its economic impact and future role as a renewable energy source. Reviews in Chemical Engineering, 36(3), pp. 401–421. https://doi.org/10.1515/revce-2017-0103.

Manogaran, M.D., Shamsuddin, R., Yusoff, M.H.M., Lay, M. and Siyal, A.A. 2022. A review on treatment processes of chicken manure. Cleaner and Circular Bioeconomy, 2, p.100013. https://doi.org/10.1016/j.clcb.2022.100013.

Marjolaine. 2017. Electricity and heat production from biogas CHP: discover technologies, Biogas World. https://www.biogasworld.com/news/biogas-chp-discover-technologies/ (Accessed: 29 January 2024).

Matos, C.F., Paes, J.L., Pinheiro, É.F. and De Campos, D.V. 2017. Biogas production from dairy cattle manure, under organic and conventional production systems. Engenharia Agrícola, 37, pp.1081-1090. https://doi.org/10.1590/1809-4430-eng.agric.v37n6p1081-1090/2017.

McVoitte, W.P.A. and Clark, O.G. 2019. The effects of temperature and duration of thermal pretreatment on the solid-state anaerobic digestion of dairy cow manure. Heliyon, 5(7). https://doi.org/10.1016/j.heliyon.2019.e02140.

Miah, M.R., Rahman, A.K.M.L., Akanda, M.R., Pulak, A. and Rouf, M.A. 2016. Production of biogas from poultry litter mixed with the co-substrate cow dung. Journal of Taibah university for science, 10(4), pp.497-504.

Mohanty, M.K., Mohanty, R.C. and Ray, N.H.S. 2013. A Study on application of biogas as fuel in compression igni-tion engines. International Journal of Innovations in Engineering and Technology, 3(1), pp. 1–8. https://www.researchgate.net/publication/330701506.

Molekoa, K. 2023. Hydro electricity dispersed through a complex national grid system of high initial investments and maintenance. https://riseint.org/ritc2018/wp-content/uploads/sites/4/gravity_forms/11-668ee6dabb93228a6b74b6d0fd14787c/2019/01/15-Kenny-Molekoa.pdf (Accessed: 2 June 2023).

Moreroa, M., Malematja, T.P. and Ijoma, G.N. 2024. Integrating the circular economy model into the management and treatment of Fischer–Tropsch effluents—a conversion of waste to energy (biogas) opportunity. IET Renewable Power Generation, pp. 1–13. https://doi.org/10.1049/rpg2.12976

Moretti, E.R., Roston, D.M., da Silva, A.J. and Reyes, I.P. 2023. Biogas from aquatic plants: A bioenergetics incentive for constructed wetlands usage. Heliyon, 9(2). https://doi.org/10.1016/j.heliyon.2022.e12537

Mrosso, R., Mecha, A.C. and Kiplagat, J. 2023. Characterization of kitchen and municipal organic waste for biogas production: Effect of parameters. Heliyon, 9(5), p. e16360. https://doi.org/10.1016/j.heliyon.2023.e16360.

Mueni, P. and Apindi, C. 2023. Prepaid electricity rates in South Africa 2023: how does it work?, Briefly. https://briefly.co.za/105425-prepaid-electricity-rates-south-africa-work.html (Accessed: 27 June 2023).

Nagy, G., Takács, A. and Kállay, A.A. 2019. The energy aspects of biogas production from sheep ma-nure. Carbon, 29, pp.37-70.

Ndubuisi-Nnaji, U.U., Ofon, U., Asira, A.E., and Dickson, N.J. 2023. Anaerobic digestion of untreated manure: Envi-ronmental risk assessment of resultant digestates. World Journal of Applied Science & Technology, 14(1b), pp. 73–79. https://doi.org/10.4314/wojast.v14i1b.73.

Ngwabie, N.M., Chungong, B.N. and Yengong, F.L. 2018. Characterisation of pig manure for methane emission modelling in Sub-Saharan Africa. Biosystems Engineering, 170, pp. 31–38. https://doi.org/10.1016/j.biosystemseng.2018.03.009.

Ogejo, J.A., Wildeus, S., Knight, P. and Wilke, R.B. 2010. Estimating goat and sheep manure production and their nutrient contribution in the Chesapeake Bay watershed. Applied engineering in agriculture, 26(6), pp.1061-1065. https://doi.org/10.13031/2013.35912.

Okareh, O.T., Adeolu, A.T. and Shittu, O.I. 2013. Enrichment of pig dung with selected crop wastes for the production of biogas. International Research Journal of Medicine and Medical Sciences, 04(04). https://doi.org/10.14303/irjm.2012.093.

Okewale, A.O. and Babayemi, K.A. 2018. Anaerobic co-digestion of pig and poultry droppings with elephant grass for the production of biogas. Journal of Renewable Energy and Smart Grid Technology, 13(1), pp. 50–64.

Olowoyeye, J. 2013. Comparative studies on biogas production using six different animal dungs. Journal of Biology, Agriculture and Healthcare, 3(15), pp. 7–12. www.iiste.org.

Otobrise, C., Udubor, C.W. and Osabohien, E. 2022. Kinetics of biogas production from goat dung and pawpaw seed. Oriental Journal Of Chemistry, 38(4), pp. 914–923. https://doi.org/10.13005/ojc/380411.

Pereira, F.E.D.A., Rosa, A.P., Borges, E.S., Otenio, M.H., Souza, L.D.D., do Nascimento, J.E. and Borges, A.C. 2023. Anaerobic co-digestion of swine and laying hen waste for biogas generation and digestate quality. Engenharia Agrícola, 43, p.e20220124.

Ramírez, M., Gómez, J.M., Cantero, D., Ramírez, M., Gómez, J. and Cantero, D. 2015. Biogas: sources, purification and uses. Hydrogen and Other Technologies, 11(12), pp.296-323.

Risberg, K., Cederlund, H., Pell, M., Arthurson, V. and Schnürer, A. 2017. Comparative characterization of digestate versus pig slurry and cow manure–Chemical composition and effects on soil microbial activity. Waste manage-ment, 61, pp.529-538.

Rizzo, P.F., Salinas, M.C., Della Torre, V., Diez, J.P., Sallesses, L.F., Riera, N.I., Pathauer, P.S., Komilis, D. and Sánchez, A. 2022. Effect of poultry manure-derived compost on the growth of eucalypts spp. hybrid clones. Pro-cesses, 10(11), pp.2182.

Rosenberg, L. and Kornelius, G. 2017. Experimental investigation of biogas production from feedlot cattle manure. Journal of Energy in Southern Africa, 28(4). https://doi.org/10.17159/2413-3051/2017/v28i4a1753.

Sanchez, C. and Wilkie, A.C. 2017. Bioenergy production potential from small ruminant manure. Journal of Under-graduate Research, 18(3), pp. 1–4.

Sankaran, S., Sivaprakasam, S. and Velayutham, T. 2019. Biogas production by co-digestion of municipal solid waste generated from vegetable market area and sheep dung. Journal of Emerging Technologies and Innovative Re-search, 6(5), pp. 386–397. www.jetir.org.

Schoenian, S. 2021. A beginner’s guide to raising sheep, Sheep 201. https://www.sheep101.info/201/ (Accessed: 27 November 2023).

Singh, D., Tembhare, M., Machhirake, N. and Kumar, S. 2023. Biogas generation potential of discarded food waste residue from ultra-processing activities at food manufacturing and packaging industry. Energy, 263, pp.126138.

Sutaryo, S., Adiwinarti, R., Abi Sudrajad, M., Sari, T.Y.K., Khayati, L.N., Ward, A.J. and Purnomoadi, A. 2021. En-hancing methane production of dairy cow manure by co-digestion with modified cassava flour waste wa-ter. Analytical methods, 120(4.24), pp.13-59.

Tateishi, T. 2016. Development of High Efficiency BP-G 300kW-Class Biogas Co-Generation System, Yanmar Ener-gy System. https://www.yanmar.com/global/about/technology/technical_review/2016/0727_1.html#:~: text=The%20BP%2DG%20power%20generation,23.3MJ%2FNm3). (Accessed: 29 January 2024).

Tian, P., Gong, B., Bi, K., Liu, Y., Ma, J., Wang, X., Ouyang, Z. and Cui, X. 2023. Anaerobic co-digestion of pig ma-nure and rice straw: Optimization of process parameters for enhancing biogas production and system stabil-ity. International Journal of Environmental Research and Public Health, 20(1), pp.804.

Toma, L., Voicu, G., Ferdes, M. and Dinca, M. 2016. Animal manure as substrate for biogas production. Engineering for Rural Development, 25(27), pp.5.

Ukpai, P.A. and Nnabuchi, M.M. 2012. Comparative study of biogas production from cow dung, cow pea and cassa-va peeling using 45 litres biogas digester. Advances in Applied Science Research, 3, pp. 1864–1869.

Vanegas, M., Romani, F. and Jiménez, M. 2022. Pilot-Scale anaerobic digestion of pig manure with thermal pretreat-ment: stability monitoring to improve the potential for obtaining methane. Processes, 10(8), pp. 1602. https://doi.org/10.3390/pr10081602.

Wedwitschka, H., Ibanez, D.G., Schafer, F., Jenson, and Nelles, M. 2020. Material characterization and substrate suit-ability assessment of chicken manure for dry batch anaerobic digestion processes. Bioengineering, 7(3), pp. 1–16. https://doi.org/10.3390/bioengineering7030106.

Werkneh, A.A. 2022. Biogas impurities: environmental and health implications, removal technologies and future per-spectives. Heliyon. Elsevier Ltd, pp. 1–16. https://doi.org/10.1016/j.heliyon.2022.e10929.

Ya’aba, Y. and Ramalan, A.S. 2020. Isolation, identification and characterization of some bacteria associated with biogas production from cow dung. Equity Journal of Science and Technology, 7(2), pp. 91–99. www.equijost.com.

Zobeashia, S.S.T., Abioye, O.P., Ijah, U.J.J. and Oyewole, O.A. 2022. Physicochemical parameters and microbial community in anaerobic digestion of organic wastes. Advance in Environmental Waste Management & Recycling, 1(1), pp. 1-12.

Downloads

Published

Issue

Section

License

Copyright (c) 2024 mabatho moreroa, Sarah Motshekga

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

.png)